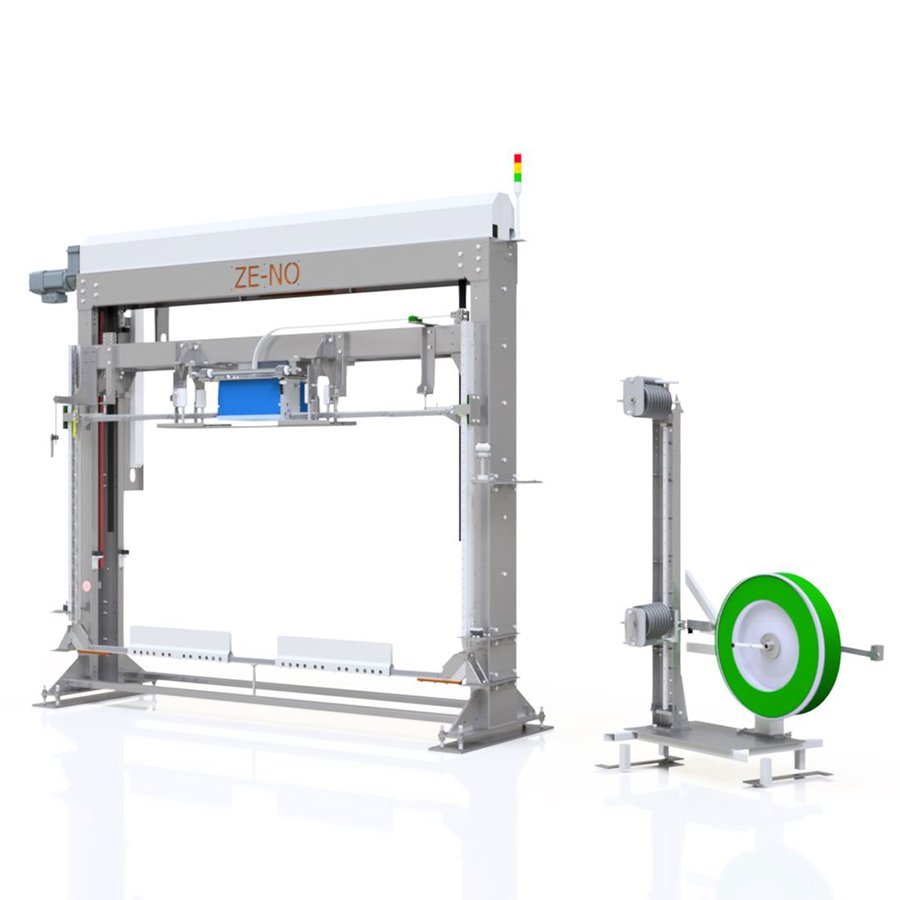

Fixed Vertical Strapping MDF (With Milling Channel)

Fixed Vertical Strapping MDF (With Milling Channel)

Stationary vertical strapping machines play an indispensable role in industrial packaging processes. These machines offer a safe and effective solution, especially when packaging MDF sheets, which are one of the dense and hard materials. The milling channel feature ensures precise strapping of MDF sheets, increasing safety in the transportation and storage processes of the products.

The main function of these machines is to create a safe packaging by tightly combining MDF sheets. The milling channel feature prevents the plate from changing shape during the strapping process by opening special channels on the surface of MDF boards. This prevents products from being damaged during transportation and maintains quality.

Paylaş

INDUSTRIES USED

Food & Beverage

Corrugated Cardboard

Paper

Building Materials

BROCHURE

VIDEO

TECHNICAL SPECIFICATIONS

• Strap Type: polypropylene (PP), polyester (PET), Steel

• Bonding Feature: Heated bonding unit

• Circle speed 2.7 m/sec - 4.7 m/sec

• Air pressure: 6 bar

• Tension Force (Newton): 2.000 – 8.000 (PET-PP) 2.000 – 20.000 (Steel)

• Ability to perform gradual stretching

• Use of 9-12 or 16-19 mm wide PET strap

• Circle Thickness (mm): 0.6 – 1.4

• 24 V/DC supply and control system in compliance with the low voltage directive

ZT FHSM Features Options:

• Titan Strapping Head K8000 Strapping Head

• Digital and easy setting feature with Siemens PCL and HMI control panel

• Adjustable distance and number of circles

• Adjustable Boiling Time

• There is an automatic product height detection system that can adjust itself according to the height of the product to be strapped.

• It has a tension balancing module to apply equal tension to every part of the product.

• Can be integrated into most production lines

• Capacity is shaped according to customer demand.

• Standard pallet dimensions 800 x 1000; 800x1200mm